3 Inch Slip On Flanges DIN 86030 SORF Flanges to Pipe Welding Slip

On Flanges Carbon Steel A105 PN 16 for Petroleum and gas industry

Introduction of DIN 86030 Hubbed Slip On Flanges:

DIN 86030 Hubbed Slip On Flanges are a specialized type of flange defined by the German Institute

for Standardization (DIN). These flanges are characterized by their

hubbed design, which provides additional strength and stability,

making them suitable for a range of industrial applications.

Specifications of DIN 86030 Slip On Flanges:

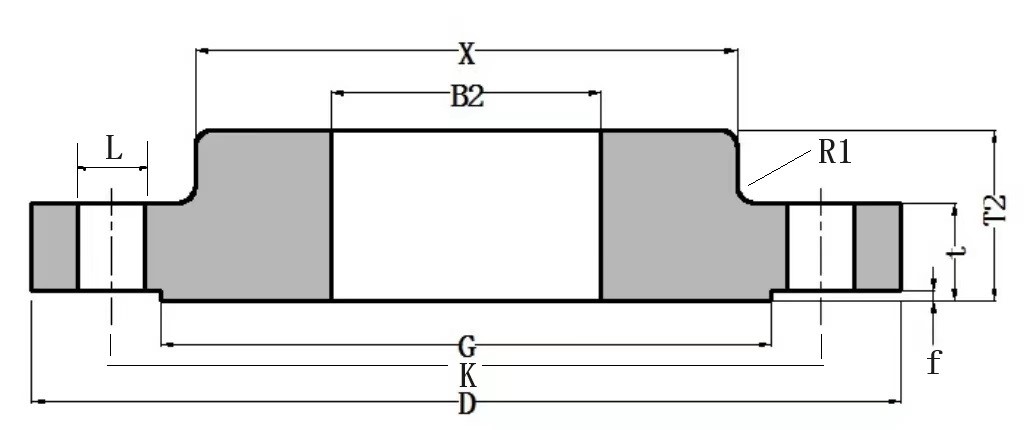

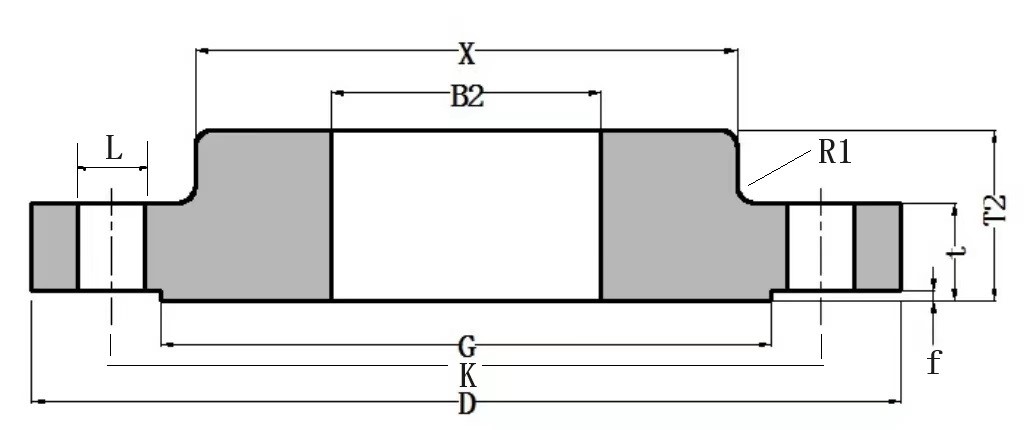

DIN 86030 Hubbed Slip On Flanges Dimensions:

| DIN 86030 Hubbed Slip-On Flanges PN 16 |

| DN | Outside Diameter | O.D.of Raised Face |

Height of Raised Face | Neck Diameter | Thickness | Dia Counter Bore | Length of Flange | Bolt circle diameter | Number of holes | Diameter of Bolt |

Radius of Corners

|

Weight

|

| D | G | f | X | t | B2 | T2 | K | Numbers | L | R1 | KG |

| 10 | 90 | 40 | 2 | 30 | 14 | 17.7 | 20 | 60 | 4 | 14 | 4 | 0.6 |

| 15 | 95 | 45 | 2 | 35 | 14 | 22 | 20 | 65 | 4 | 14 | 4 | 0.6 |

| 20 | 105 | 58 | 2 | 45 | 16 | 27.6 | 24 | 75 | 4 | 14 | 4 | 0.9 |

| 25 | 115 | 68 | 2 | 52 | 16 | 34.4 | 24 | 85 | 4 | 14 | 5 | 1.1 |

| 32 | 140 | 78 | 2 | 60 | 16 | 43.1 | 26 | 100 | 4 | 18 | 5 | 1.6 |

| 40 | 150 | 88 | 3 | 70 | 16 | 49 | 26 | 110 | 4 | 18 | 5 | 1.8 |

| 50 | 165 | 102 | 3 | 85 | 18 | 61.1 | 28 | 125 | 4 | 18 | 5 | 2.4 |

| 65 | 185 | 122 | 3 | 105 | 18 | 77.1 | 32 | 145 | 4 | 18 | 5 | 3.1 |

| 80 | 200 | 138 | 3 | 118 | 20 | 90.3 | 34 | 160 | 8 | 18 | 5 | 3.8 |

| 100 | 220 | 158 | 3 | 140 | 20 | 115.9 | 38 | 180 | 8 | 18 | 5 | 4.3 |

| 125 | 250 | 188 | 3 | 168 | 22 | 141.6 | 40 | 210 | 8 | 18 | 5 | 5.9 |

| 150 | 285 | 212 | 3 | 196 | 22 | 170.5 | 44 | 240 | 8 | 22 | 5 | 7.2 |

| 175 | 315 | 242 | 3 | 224 | 24 | 196.1 | 44 | 270 | 8 | 22 | 6 | 9.2 |

| 200 | 340 | 268 | 3 | 247 | 24 | 222 | 44 | 295 | 12 | 22 | 6 | 9.7 |

| 250 | 405 | 320 | 3 | 300 | 26 | 276 | 46 | 355 | 12 | 26 | 6 | 13.5 |

| 300 | 460 | 378 | 4 | 355 | 28 | 327 | 46 | 410 | 12 | 26 | 6 | 17.3 |

| 350 | 520 | 438 | 4 | 400 | 30 | 359 | 57 | 470 | 16 | 26 | 10 | 27.7 |

| 400 | 580 | 490 | 4 | 457 | 32 | 410 | 63 | 525 | 16 | 30 | 10 | 36.1 |

| 450 | 640 | 550 | 4 | 505 | 34 | 461 | 68 | 585 | 20 | 30 | 10 | 44.3 |

| 500 | 715 | 610 | 4 | 559 | 34 | 512 | 73 | 650 | 20 | 33 | 10 | 56.9 |

| 600 | 840 | 725 | 5 | 664 | 36 | 614 | 83 | 770 | 20 | 36 | 10 | 81.0 |

| 700 | 910 | 795 | 5 | 760 | 36 | 716 | 83 | 840 | 24 | 36 | 10 | 76.8 |

| 800 | 1025 | 900 | 5 | 864 | 38 | 818 | 90 | 950 | 24 | 39 | 10 | 99.3 |

| 900 | 1125 | 1000 | 5 | 969 | 40 | 920 | 94 | 1050 | 28 | 39 | 10 | 116.6 |

| 1000 | 1255 | 1115 | 5 | 1073 | 42 | 1022 | 100 | 1170 | 28 | 42 | 10 | 154.1 |

1.Dimensions are in millimeters(mm).

2.Dimensions can be specified by different purchasers.

Common Grades of DIN 86030 Carbon Steel Slip On Flanges:

ASTM A105: This is a common grade of carbon steel used for slip on flanges.

It is a forged carbon steel specifically designed for

high-temperature service and offers excellent weldability and

toughness.

ASTM A350 LF2: LF2 is a low-temperature carbon steel grade commonly used for slip

on flanges in applications where low-temperature toughness is

required.

ASTM A694 F52/F60/F65/F70: These grades are high-yield carbon steel materials used for slip

on flanges in applications requiring high strength and impact

resistance.

Design and Features of DIN 86030 Carbon Steel Slip On Flanges:

Hubbed Design: The flanges have a hub that helps distribute the stress more

evenly across the flange, reducing the risk of warping or damage

under high pressure.

Slip On Feature: These flanges are slipped over the pipe and then welded in place.

This design simplifies the alignment and installation process

compared to other flange types.

Material Options: They are available in various materials such as stainless steel,

carbon steel, and alloy steel, which can be chosen based on the

specific requirements of the application, such as corrosion

resistance or strength.

Standard Dimensions: The dimensions of these flanges comply with the DIN 86030

standard, ensuring interchangeability and compatibility with other

standard components.

Pressure Handling: Suitable for moderate to high-pressure

applications, these flanges ensure safety and reliability in

various industrial settings.

Weldable: They can be welded to the pipe, creating a strong, leak-proof

connection that can withstand significant stress and pressure.

Facing Options: Multiple facing options are available, such as raised face (RF),

flat face (FF), and ring-type joint (RTJ), which provide different

sealing solutions to match specific needs.

Gasket Compatibility: They are designed to form a tight seal with compatible gaskets,

preventing leaks and maintaining the integrity of the piping

system.

The Differences between carbon steel hubbed slip on flanges and

stainless steel hubbed slip on flanges:

Composition:

- Carbon Steel Hubbed Slip On Flanges: These flanges are primarily made from carbon steel, which contains

iron and carbon as the main elements. The carbon content in carbon

steel can vary, affecting its mechanical properties.

- Stainless Steel Hubbed Slip On Flanges: These flanges are made from stainless steel, which contains iron,

chromium, and varying amounts of other elements such as nickel and

molybdenum. The presence of chromium provides stainless steel with

its corrosion-resistant properties.

Corrosion Resistance:

- Carbon Steel Hubbed Slip On Flanges: Carbon steel flanges are susceptible to corrosion, especially in corrosive environments

or when exposed to moisture. They require protective coatings or

surface treatments to enhance their corrosion resistance.

- Stainless Steel Hubbed Slip On Flanges: Stainless steel flanges have excellent corrosion resistance due to the presence of

chromium. The chromium forms a passive oxide layer on the surface,

protecting the steel from corrosion caused by chemicals, moisture,

and atmospheric conditions.

Strength:

- Carbon Steel Hubbed Slip On Flanges: Carbon steel flanges have high strength and good mechanical properties, making them

suitable for high-pressure and high-temperature applications.

- Stainless Steel Hubbed Slip On Flanges: Stainless steel flanges have lower strength compared to carbon steel flanges. However,

they still offer sufficient strength for many applications and

provide excellent resistance to stress corrosion cracking.

Cost:

- Carbon Steel Hubbed Slip On Flanges: Carbon steel flanges are generally more cost-effective compared to stainless steel

flanges. They are widely available and have lower material costs.

- Stainless Steel Hubbed Slip On Flanges: Stainless steel flanges are generally more expensive due to the higher cost of stainless

steel as a raw material. However, their superior corrosion

resistance and longevity may offset the initial higher cost in

certain applications.

Suitability for Specific Applications:

- Carbon Steel Hubbed Slip On Flanges: Carbon steel flanges are commonly used in applications where strength and

cost-effectiveness are priorities. They are suitable for various

industries, including oil and gas, chemical processing, and power

generation.

- Stainless Steel Hubbed Slip On Flanges: Stainless steel flanges are ideal for applications that require excellent corrosion

resistance, such as food processing, pharmaceuticals, water

treatment, and marine environments.

The main differences between carbon steel and stainless steel hubbed slip on flanges lie in their composition, corrosion resistance, strength, and

cost. Carbon steel flanges are generally more cost-effective but require additional measures

to enhance corrosion resistance, while stainless steel flanges offer excellent corrosion resistance but at a higher cost. The

choice between the two depends on the specific requirements of the

application, including the operating environment, budget, and

desired longevity of the flange.

Applications of DIN 86030 Carbon Steel Slip On Flanges:

Oil and Gas Industry: DIN 86030 Carbon steel slip on flanges are commonly used in the oil and gas industry for various

applications such as pipelines, refineries, and petrochemical

plants. They are suitable for low to moderate pressure and

temperature environments.

Power Generation: DIN 86030 Carbon steel slip on flanges find application in power generation facilities, including power

plants and thermal power stations. They are used for connecting

pipes in steam, water, or gas distribution systems.

Water and Wastewater Treatment: DIN 86030 Carbon steel flanges are utilized in water treatment plants, wastewater treatment

facilities, and desalination plants. They provide secure

connections for pipes carrying water, chemicals, or other fluids.

Construction and Infrastructure: DIN 86030 Carbon steel slip on

flanges are widely used in construction projects such as buildings,

bridges, and infrastructure. They are suitable for connecting pipes

in HVAC systems, plumbing, and fire protection systems.

Industrial Processes: DIN 86030 Carbon steel slip on flanges are employed in various industrial processes, including

manufacturing, chemical processing, and mining. They are used to

connect pipes in conveying fluids, gases, or abrasive materials.